Paulownia

Paulownia timber is widely used in Asia. It is light, odourless, and easily worked. In colour it varies from silver-grey (highly prized in Japan) to light brown. It has a low basic density but is easy to dry and, although unsuitable for structural use, has physical and mechanical properties that are acceptable for other purposes. It is straight-grained and easy to plane to a glossy surface. Overseas reports indicate that it has good natural durability, but results in New Zealand suggest that it should be classified as non-durable. The pale brown heartwood is difficult to distinguish from the slightly lighter sapwood, which is only found in the outer 1-2 annual rings.

| Properties | N.Z. Paulownia |

|---|---|

| Basic Density | 285-300kg/m3 |

| Air-dry density (11% moisture content) | 335-340 kg/m3 |

| Tangential shrinkage (green to 12% moisture content) | 1.8-2.0% |

| Radial shrinkage (green to 12% moisture content) | 0.8-0.9% |

| Hardness*The hardness rating of a timber species is measured by the Janka Test. This is a standard test which measures the penetration into the timber of a common load and projectile. The results relate to a hardness capacity of the material and are expressed in kN. Typical 35 year old radiata pine has hardness of 4.2kN. (dry) | 1.3-1.4 kN |

| Modulus of rupture (MPa) | 40 |

| Modulus of elasticity (GPa) | 4.0 |

| Compression parallel (MPa) | 23 |

| Shear parallel (MPa) | 5.3 |

Characteristic features of paulownia timber are:

- Lightness – Paulownia is the lightest known timber other than balsa;

- High strength-to-weight ratio (although basic strength is low);

- Low shrinkage;

- Very good dimensional stability;

- Resistance to insect damage;

- Low thermal conductivity;

- Low temperature conductivity;

- Good electrical insulation properties;

- Resistance to fungal rots (but not to surface moulds).

Uses

Paulownia wood has been used for a wide variety of purposes in China and Japan for more than 2500 years. The main products are:

- Housing components that do not require high timber strength.

- Aircraft fittings requiring light wood.

- Veneers for plywood and for facing lower quality wood.

- Furniture, especially drawers. This is because the wood fits snugly and is insect-resistant. In Japan it is used to make tonsui (dowry chests).

- Musical instruments, particularly sounding boards.

- Barrels, especially those used for acids, wine, etc.

- Beehives, for which light-weight and good insulating properties are needed.

- Aqueducts, in rural areas.

- Handcrafts, because the wood is easy to carve and turn.

- Rice bowls and other utensils, especially in earlier times.

- Wooden boxes for gifts or storage of paintings and scrolls.

- Charcoal for fireworks and filters.

- Wood pulp – which is white and strong.

- Wood shavings for packaging and insulation.

- Packaging, especially light crates.

- Coffins (an ancient use in China).

- Pattern-making, where timber stability is required.

In New Zealand Paulownia is most likely to be used in the manufacture of veneers and furniture.

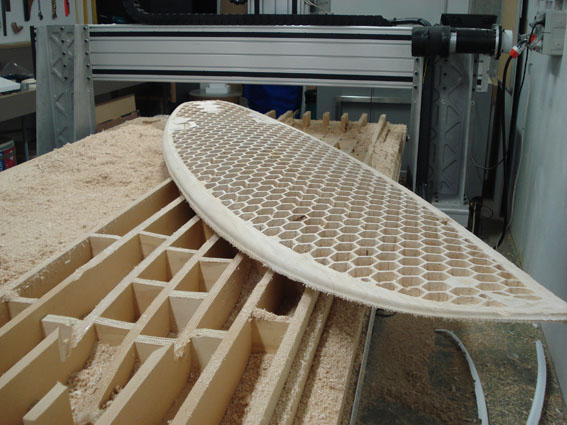

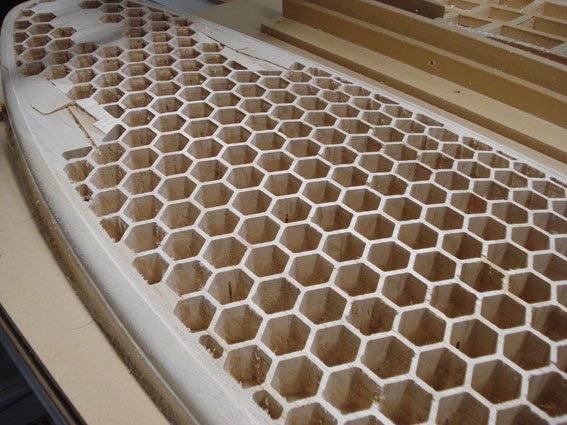

The popularity of the wooden surfboard has been on the increase in recent times with technology playing a part in producing a quality product. Paulownia is the premier wood for producing surfboards because it has a good weight to strength ratio, is light, and absorbs less salt water than many other types of wood. Paulownia surfboards are usually finished with a natural oil which prevents damage from sun on the board and salt drying on the surface.

A further attraction with paulownia surfboards, kayaks and boats is the small environmental impact compared with fibreglass products, which are associated pollutants and long decomposition time.

Availability

May be available in the Marketplace.

Showcase

Photo courtesy Paulownia enterprises NZ www.paulownia.co.nz

Disclaimer: While every effort is made to ensure the accuracy of the information provided on this site, Farm Forestry Timbers Society do not accept liability for any consequences arising from reliance on the information published. If readers have any doubts about acting on any articles they should seek confirming, professional advice.

Farm Forestry New Zealand

Farm Forestry New Zealand Farm Forestry Timbers - Headlines

Farm Forestry Timbers - Headlines